Reliable Installation Practices for Steel Buildings: Enhancing Your Construction Process

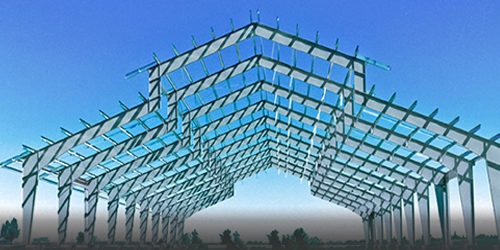

In the world of building, effectiveness is a keystone of success. When it involves putting up steel structures, the procedure can be substantially streamlined by executing effective setup methods. From precise planning to the utilization of pre-engineered components, each action plays a vital duty in accelerating the building timeline. However, the key exists not just in speed but also in precision and top quality. By diving into the world of sophisticated installation strategies and making certain rigid high quality control measures, the possibility for maximizing the whole construction procedure ends up being not just an opportunity but a practical fact.

Planning for Efficiency

When intending to optimize performance in steel structure installation, meticulous planning is vital. Appropriate preparation sets the foundation for a organized and smooth building process, ultimately saving time and resources.

Additionally, effective interaction among all stakeholders is extremely important throughout the preparation phase. Normal meetings and updates aid keep every person on the exact same page, lessen misunderstandings, and promote a collaborative workplace - steel buildings. By spending effort and time right into thorough planning, steel building installment can be implemented with precision and efficiency

Using Pre-Engineered Parts

Reliable steel building installment practices can be even more boosted by leveraging the usage of pre-engineered elements. Pre-engineered parts are created and made off-site to precise specs, ensuring compatibility and simplicity of setting up throughout the building procedure. By incorporating pre-engineered components such as beam of lights, panels, columns, and trusses, builders can enhance the installation process, decrease on-site labor demands, and decrease construction waste.

One trick benefit of making use of pre-engineered components is the significant time cost savings they use. Given that these components are fabricated in a controlled atmosphere, they get here at the construction site ready for quick and effective installment. This not just speeds up the total construction timeline yet additionally helps to decrease project hold-ups and linked costs.

In addition, pre-engineered components are crafted for optimum performance and architectural stability, making certain the lasting resilience and stability of the steel structure. By making use of these standard elements, home builders can accomplish consistent quality throughout different projects while additionally profiting from cost financial savings linked with minimized material waste and labor expenses.

Optimizing Building And Construction Sequencing

To take full advantage of productivity and effectiveness in steel structure installation, calculated optimization of construction sequencing is critical. By meticulously imp source planning the order in which tasks are implemented, construction teams can lessen downtime, reduce material handling, and enhance the total building procedure.

Carrying Out Advanced Installment Techniques

Executing advanced installment methods boosts the performance and quality of steel structure construction jobs. By integrating innovative methods such as computer-aided design (CAD) for precise preparation, prefabrication of components off-site, and use of advanced equipment like robotic welders, building and construction teams can significantly simplify the installation procedure. Prefabrication decreases on-site labor needs and building and construction time by making structure aspects in a controlled atmosphere, reducing mistakes and rework.

Making Certain High Quality Control

Structure upon the usage of their website innovative installation techniques, preserving stringent high quality control actions is critical in making certain the structural integrity and dependability of steel structure projects. Quality control starts with the selection of high-grade materials that satisfy market criteria and specifications. Regular assessments throughout the building and construction process help determine any type of inconsistencies from the layout or prospective issues that might jeopardize the structure's toughness.

Documentation is a vital facet of quality assurance, ensuring that all steps in the setup process adhere to the authorized laws and strategies. This consists of recording examinations, product qualifications, and any kind of alterations made throughout building and construction. Applying a clear communication procedure among team members and subcontractors helps streamline the quality assurance procedure and resolve any kind of worries immediately.

Conclusion

To conclude, browse around this web-site taking on efficient setup techniques for steel buildings is important for simplifying the construction process. By thoroughly planning, using pre-engineered parts, optimizing sequencing, carrying out innovative techniques, and guaranteeing quality assurance, building and construction jobs can be finished faster and efficiently. These methods not just conserve time and resources but also add to the general success of the task. It is essential to prioritize efficiency in order to make the most of efficiency and accomplish effective results in steel structure construction.

To make best use of performance and efficiency in steel building installation, strategic optimization of construction sequencing is paramount. On the whole, by maximizing building sequencing, steel building installation can be finished extra successfully, conserving time and expenses in the process.

Executing advanced setup techniques boosts the performance and high quality of steel building construction projects. By focusing on top quality control throughout the setup process, construction groups can provide steel buildings that are not only effective however reliable and additionally resilient.

In conclusion, embracing efficient installment practices for steel structures is important for streamlining the building and construction process.

Comments on “Versatile Steel Buildings: Suitable for Storehouses, Workshops, and Storage Facilities”